Hydraulic Rod Pumps, Intl. , founded in 1987 in Placentia CA is a world leader in hydraulic rod pumping technology. For over 3 decades, the company had been focusing and developing the world's most durable and advance rod pumping equipment. Their technology & equipment is field proven and had been highly successful in delivering ultra reliable performance for producers worldwide.

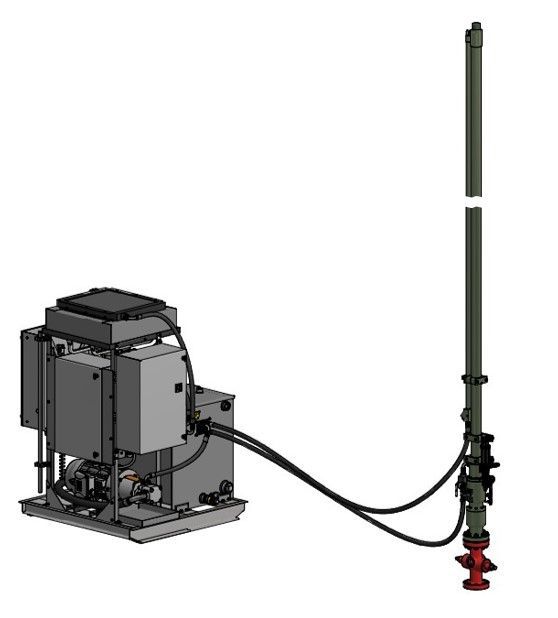

Hydraulic rod pumps provide an alternative to traditional beam units, ESP’s, PCP’s, Gas Lift, etc. combining the reliability and durability of a long stroke rod pump with a minimal wellhead footprint. Hydraulic rod pumps are ideal for well production testing, liquid loaded wells & troublesome wells, and deep or deviated wells, in addition to wells where a traditional rod pumps are considered.

The plug & play package comes with the hydraulic cylinder and a hydraulic power unit, well operation is monitored & controlled remotely. Advance controls include pump-off controller, dyno-cards, remote web-based monitoring & control, fluid level monitoring.

Benefits & Advantages of the HRP Hydraulic Rod Pump

Specifications

36 to 336 inches

Stroke Length

up to 53,376 lbs

Peak Polished Rod Load

10 to 150 HP

Power Rating

5000 psig

Component Pressure Rating

150 deg C

Design Temperature

60, 100, 200 US Gallons

Hydraulic Oil Reservour Capacity

3000 psig

Continuous Vane Pump Rating

2.5 to 5.0 inches

Cylinder Sizes

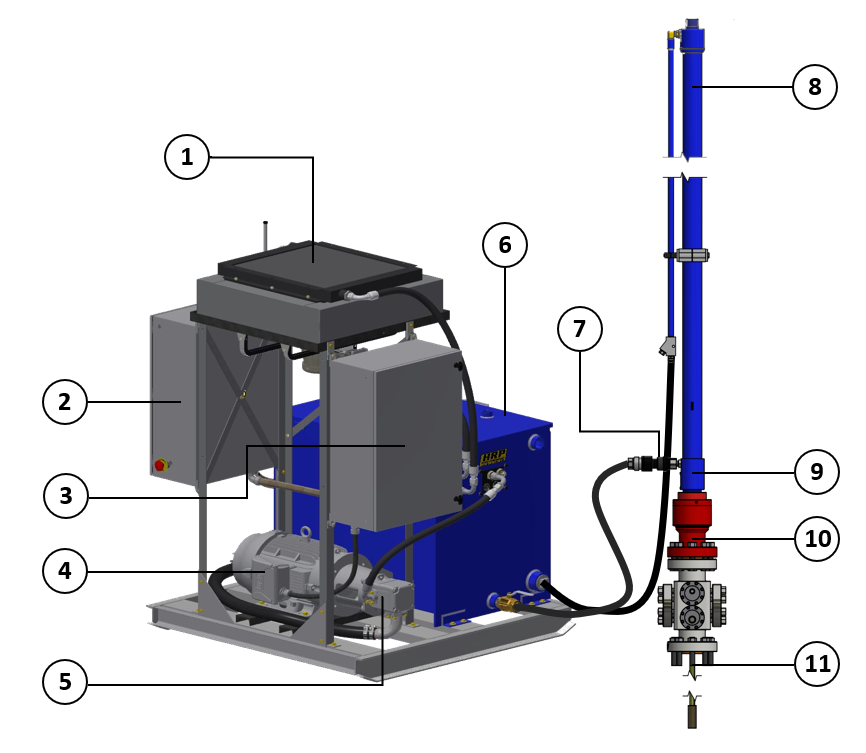

Bill of Materials

| Item | Description |

|---|---|

| 1 | Cooling System |

| 2 | Control Panel with Integrated 3G/Wifi Modem |

| 3 | Advance Pump Controller |

| 4 | Prime Mover |

| 5 | Hydraulic Vane Pump |

| 6 | Hydraulic Reservoir with valving system and sensors |

| 7 | Hydraulic Fluid Intake |

| 8 | Hydraulic Cylinder with Piston |

| 9 | Integrated Sealing System |

| 10 | Wellhead Adapter |

| 11 | Intergated Polished Rod |

Long & Slow is the way to go

Rod pump technology has evolved only slightly in the last three decades with one exception: Long stroke and ultra-long stroke HRP pumping units. The necessity to maximize economical efficiencies of rod-pumped oil and gas wells has created a high demand for longer stroke lengths, as most other elements of the rod-pumped well present little room for improvement. The benefits of long and ultra-long stroke pumping units includes increased production rates, reduced bottomhole equipment wear, decreased rod string fatigue, minimized tubing wear in both vertical and directional wells and lower occurrences of bottomhole pump gas locking. These benefits are discussed below in an overview of applied long stroke and ultra-long stroke pumping technology.

Explore below on the benefits of pumping your well long & slow.

Explore below on the benefits of pumping your well long & slow.

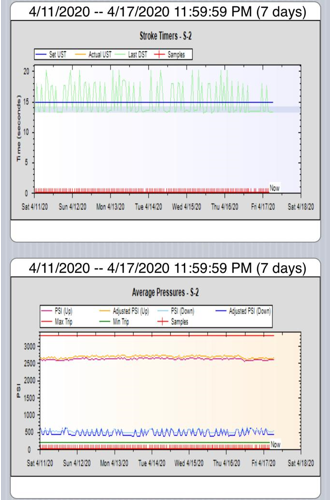

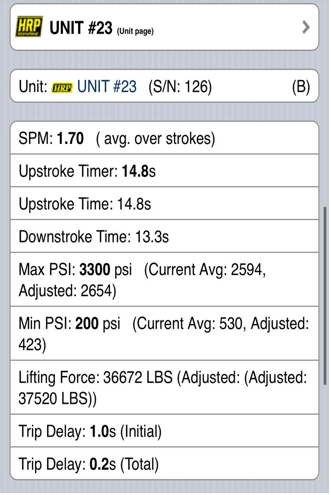

Advance Pump Controller

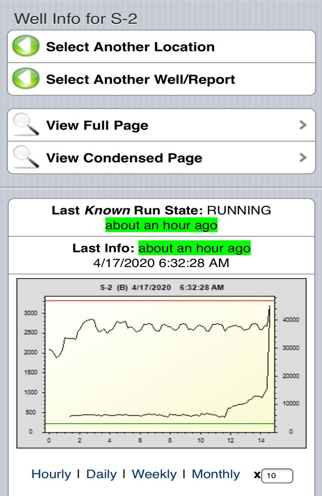

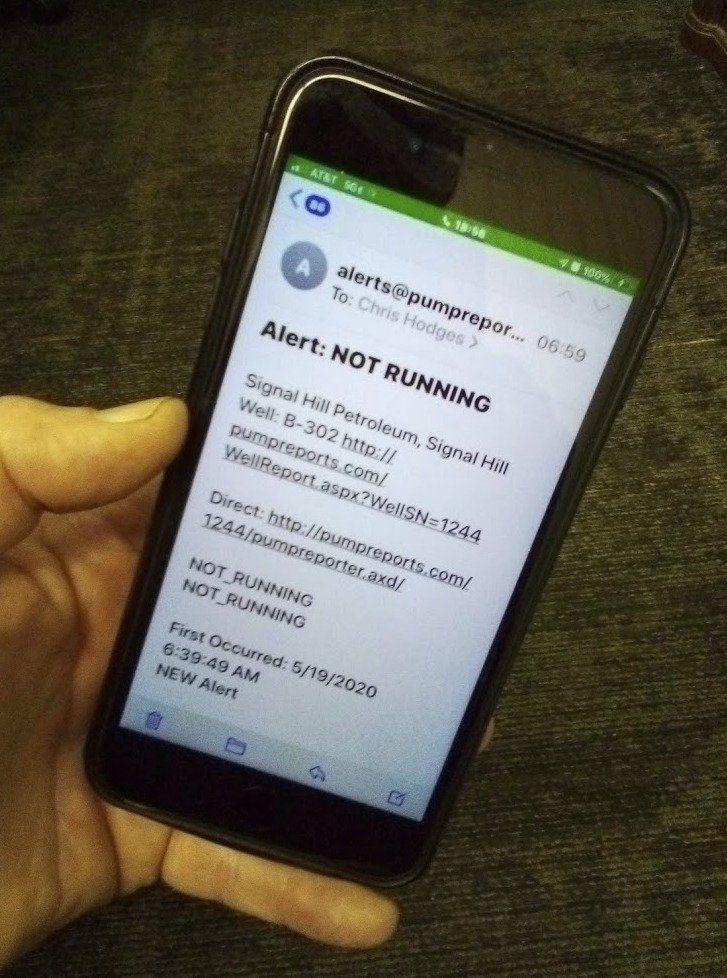

HRPI equipment provides advanced computer control, monitoring, and diagnostics. The most notable control feature of the system is the ability to remotely adjust the well's Strokes Per Minute (SPM). This allows for a more optimized pump rate given changing conditions. Live dyno graphs are streamed as they are collected, stored both locally and on a central webbased analysis server.

Web based monitoring, alerting, and analysis is provided through http://pumpreports.com. Access to historical well information, current operating parameters, dynos, and trend graphs are available securely from any standard web browser.

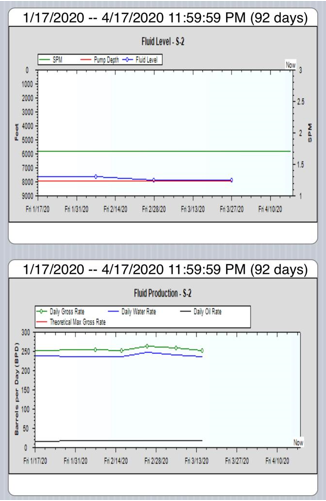

Fluid Level vs Pump Speed

Correlating fluid levels with stroke rate enables operators to optimize the pump rate for a desired FOP. The HRP Advance Controller uses a hydraulically derived fluid level to perform fluid level monitoring. The system allows the option for manual speed adjustment or automatically adjust the speed based on predetermined set points.

Note increases in the stroke rate (green) result in decreases in fluid level (blue)

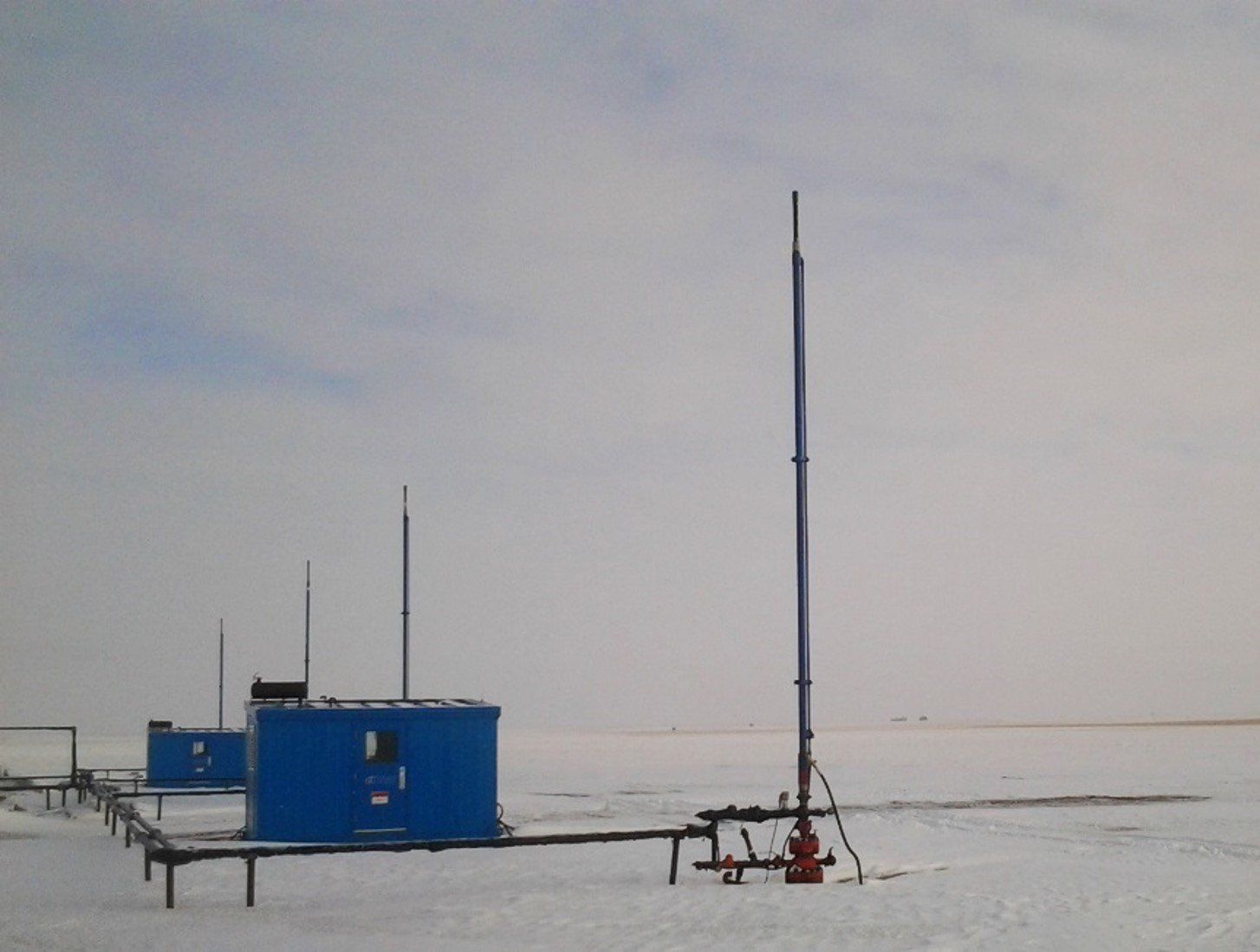

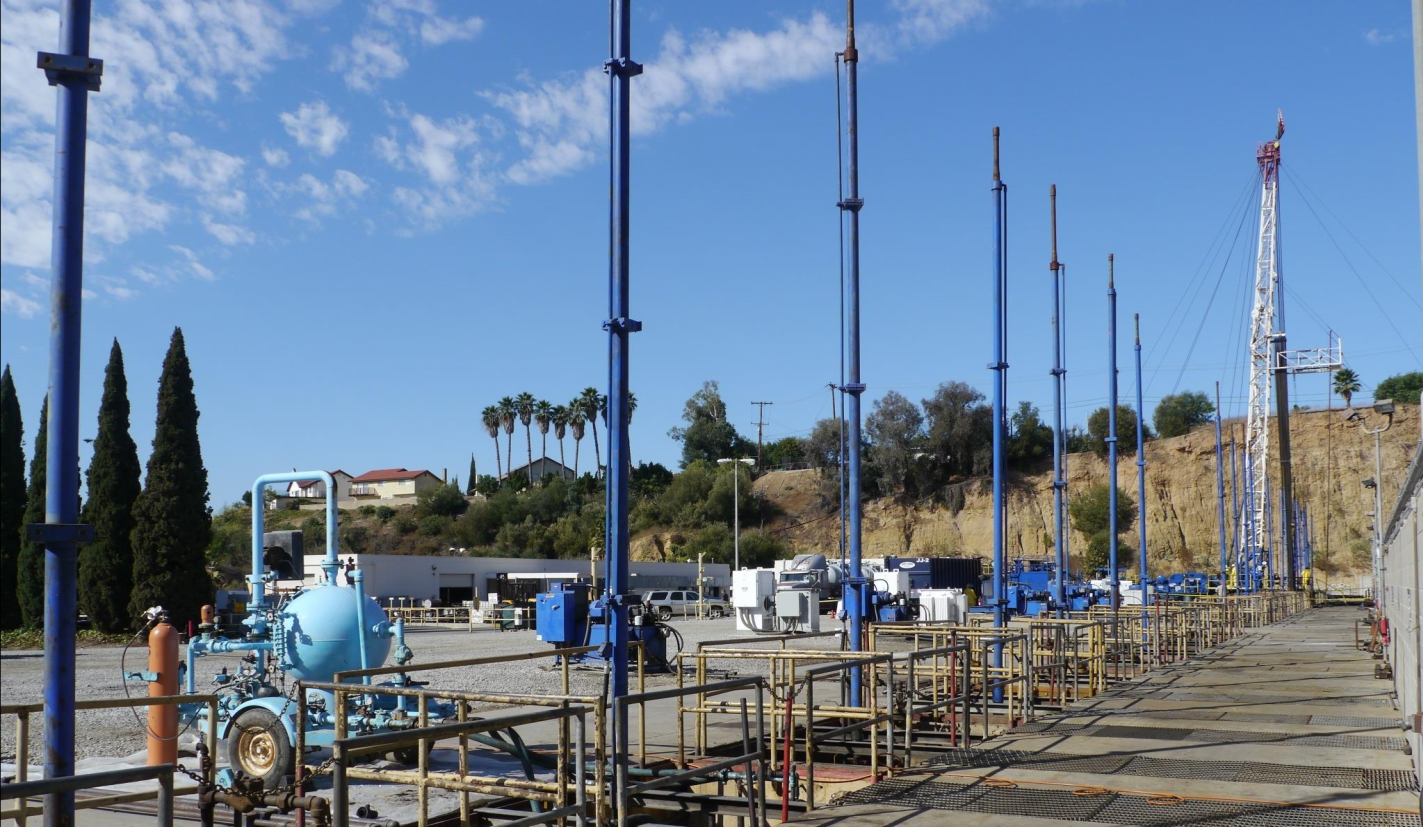

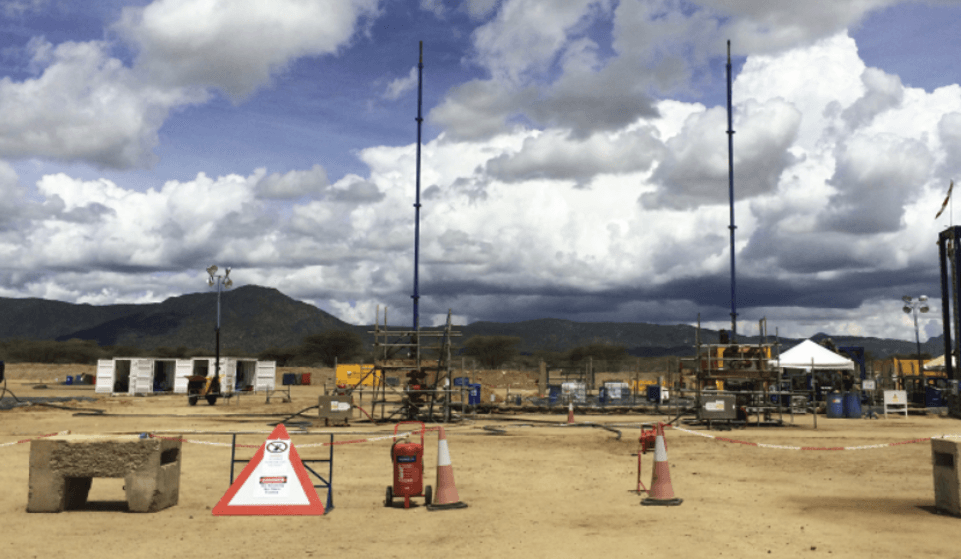

HRP Installation Gallery

HRP's Long Stroke Hydraulic Rod Pumps are used worldwide in many applications including Deep Wells, Deviated Wells, Stripper Wells, Pad Wells, Dual Completions, Residential & Sensitive Areas, Height & Space Restrictions, Shallow Wells, Offshore Platforms, Urban Drill Sites, Directional Wells, High Density Fields, Agricultural Installations, Visually Sensitive Areas.